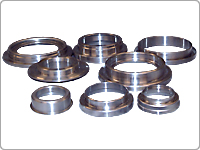

Precision Metal Stamping Services

Known nationally for over 60 years, Columbia Metal Spinning is proud to provide high quality in-house metal manufacturing services with state-of-the-art machinery. This tradition is exemplified by our precision metal stamping services. By investing in advanced metal forming equipment, we are able to cost effectively produce components with high accuracy and low production costs. Geared for the production of prototypes, short runs, or contract manufacturing, we can work with a variety of materials, including aluminum, brass, copper, Hastelloy, bronze, galvanized steel, and Inconel, just to name a few. We utilize a 165 ton stamping press, and a 250 ton hydraulic press with a 40″ square bed, this allows us to stamp parts with a maximum diameter up to 30″ and a maximum thickness of .250″, all done to tolerances of ±.001″ or tighter. These advanced capabilities allow us to stamp products such as hardware, connectors, end caps, medical diaphragms, electronics, and medical components.

Our products achieve very high levels of quality, meeting standards set by the ANSI, ASTM, ISO, IATF, and Mil-Spec. To learn more about the high quality metal stamping see the table below, or contact us directly.

![]()

Precision Metal Stamping Capabilities

Metal Stamping General Capabilities

Prototype

Short Production Runs

Contract Manufacturing

Production Method

Punch Press

Compound Die

Short Run DieDeep Drawn

Industry Focus

Oil Field

Aerospace

Architecture

Automotive

Retail

Environmental

Analytical Instrument

Fuel Cell

Thermal and Power ManagementAgricultural

Cryogenic

Food

Lighting

Railroad

Electronic

Medical

Military/Government

Production Capabilities

Round Parts

Deep DrawSingle Stroke

Materials

Aluminum

Brass

Copper

Hastelloy B

Hastelloy C

Hastelloy S

Hastelloy X

Haynes 188

Haynes 230

Monel

BronzeGalvanized Steel

Inconel 600

Inconel 625

Inconel 718

Stainless Steel 300 Series

3Stainless Steel 400 Series

Steel

Titanium

Corten

Exten

4130

Stamping Product

Hardware

Connectors

Sensor Components

Electronic ConnectorsEnd Caps

Medical Diaphragms

Filter Components

Medical Components

Desired File Format

AutoCAD (DWG)

Bit Mapped Graphics (BMP)

Drawing Interchange Format, or Drawing Exchange Format (DXF)

Graphics Interchange Format (GIF)

Initial Graphics Exchange Specification, ANSI File Format (IGES)

Joint Photographic Experts Group (JPG or JPEG)

MasterCam (MDX, MC8, MC9, SET)

Portable Document Format (PDF)

SolidWorks (SLDPRT,SLDDRW,SLDDRT)

Standard for the Exchange of Product Model Data (STEP)

Tagged Image File Format (TIFF)

Stamping Equipment Capabilities

Stamping Press up to 165 Tons

Hydraulic Press up to 250 Tons

Bed Size: 40″ Square

Stamping Dimensions

Maximum Part Diameter: 30″

Maximum Part Thickness: .250″

Stamping Tolerance

+/-.001 or Tighter

Secondary Process

Drilling

Tapping

Notching

Piercing

GrindingIn-house Milling

Machining

Joggling

Beading

Slotting

Secondary Services

Painting

Plating

LaserAnodizing

Welding

Inspection Process

3 Coordinate Measurement Machines (CMM)

Micrometers & Calipers

SPC Capabilities

Ultrasonic Gauging

Surfometer

Faro Arm

Industry Standards/Associations

American National Standards Institute (ANSI)

American Society for Testing and Materials (ASTM)

International Organization for Standardization (ISO)

ISO 9001 and IATF 16949Military Specifications (Mil-Spec)

Precision Metalforming Association (PMA)

Technology & Manufacturing Association (TMA)